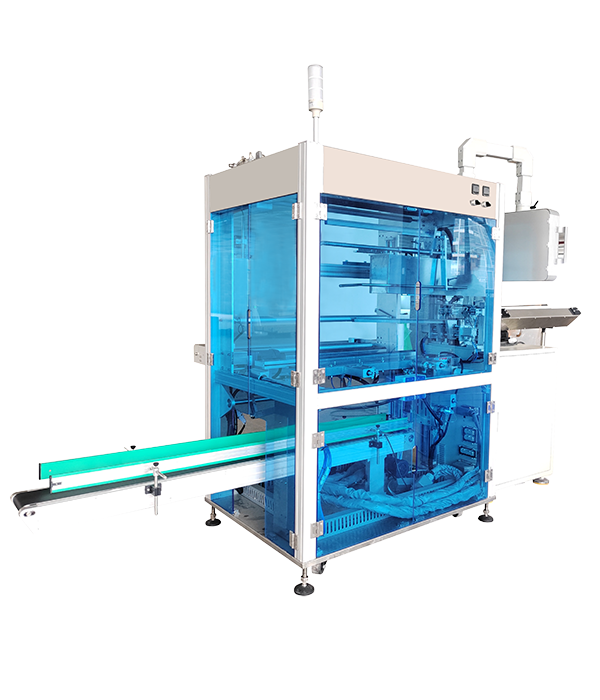

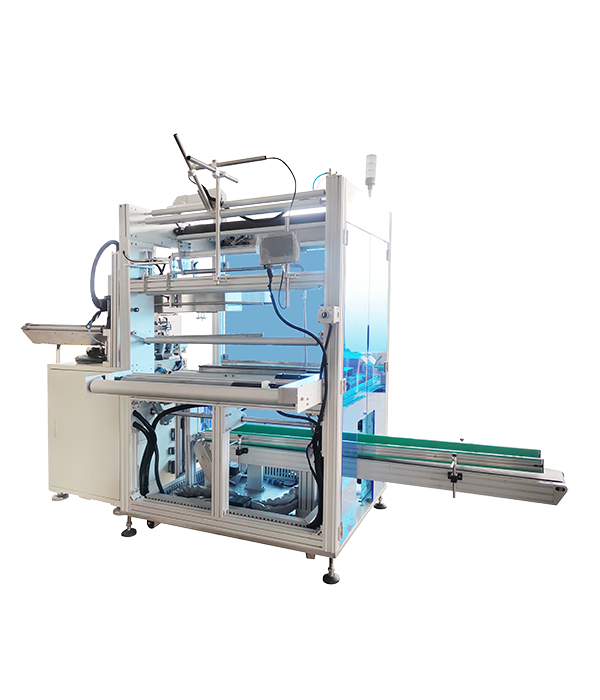

Product Introduction

Automatic Plastic Cup(Lids)Packaging Machine is fast and efficient automated packaging equipment for the production of plastic cups(lids)unmanned packaging. The formed or printed products are automatically counted and bagged by automatic control system.It can be used independently,or it can be bagged inline with the thermoforming machine,printer or rimming machine.Or the inkjet printer or labeling machine can be selected to solve the information on the packaging bag or film.The color label tracking function can be choose during the production of printer film packaging.You can install automatic packing machine and robot to realize inline packing and palletizing.and the automatic packing machine can be installed after the finished product packaging to realize inline packing.The packaging machine is mainly used in the thermoforming industry of food plastic packaging industry.The quantity is according to customer's requirement.LOGO and product information can be printed according to the customer's choice.

Product Features

1)The production speed can be adjusted.

2)With stacking,counting,feeding film sealing and cutting functions(automatic inkjet printer are optional).

3)Compact structure,stable performance,simple operation.Non-stick knives,no waste film.

4)The temperature can be adjusted according to the packing material,which is better suited to various packaging materials.

5)Without high requirement of products(cups,lids etc),its counting is more accurate,convenient adjustment,flexible replacement packaging.

6)The use of direct push design,so that the packaging movement smooth transition,There will be no loosing cups(lids),cutting cups(lids), Blocking cups(lids)etc.due to falling cup.

7)The cup is uniform,the sealing position is accurate,packaging card printing head is smooth,exquisite.

8)Reduce labor and the production cost.

9)Mechanical formulation function(memory function:store thedebugged program),avoid repeated packaging of similar specifications products debugging,waste of materials,save more time cost,improve packaging efficiency.

Specification parameters

|

Parameters |

Model |

DLJ-120 |

DLJ-160 |

|

The application shape of plastic lids |

/ |

Flat lids、Ball lids |

|

|

The material of packaging fim |

HDPE、LDPE、PP、PO、 POF、OPP、PE、CPP |

HDPE、LDPE、PP、PO、POF、 OPP、PE、CPP |

|

|

The thicknessof packaging film (μm) |

≤40 |

≤40 |

|

|

The length of packaging (mm) |

300~700 |

300~700 |

|

|

Efective packaging diameter (mm) |

76~145□ |

76~145 |

|

|

The speed of packaging for cups(bags/min) |

15~18 |

||

|

The speed of packaging for lids(bags/min) |

/ |

18~22 |

|

|

Power of main motor (KW) |

3.5 |

4.5 |

|

|

Air pressure (MPA) |

0.6~0.7 |

0.6~0.7 |

|

|

The size of machine L×W×H(mm) |

2600×1200×2100 |

3700×2700×2100 |

|

|

Weight (KG) |

500 |

600 |

|

EN

EN CN

CN