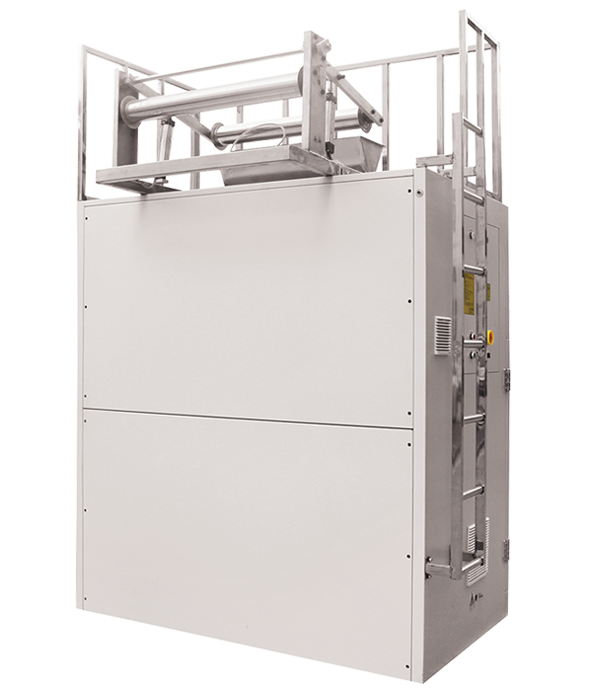

Product Introduction

Thermoforming/Three Station Online Crusher is mainly used inline with cup-making machine,automatic thermoforming machine(with tilting mold), thermoforming machine,blister machine of manufacturing environment protection disposable plastic cups,lids and bowls etc.Widely used in crushing plastic sheet,sheet with defective products,plastic package(food,medical and electronic),thermoforming edge scrap,skeletal waste after cutting or few defective goods with PP,PET,PS,PLA,PVC and biodegradable starch etc. Thermoforming/Three Station Online Crusher is working integrate with online crush,conveying,storage in full closed status.So it is avoid to pollute,labor is saved.And achieve to meet the requirement of the environmental protection. Crusher nstalled at the end of the line(back or side of trim press or stacking station)to be perfectly matched to all thermoforming machines.The production processes will be enhanced and environment willbe improved.The biggest effect is traditional productivity will be changed.It has the characteristics of beautiful, low energy consumption,high output and low noise.

Product Features

I.Traction unit:

1)The power parts are equipped with gear reducer motor from famous brand.It is convenient,durable and stable quality.

2)The rollers of traction unit are precision working from high-strength seamless steel tube,and then plate hard chrome for solidity and anti-rusty.It is elegant appearance and follow environmental protection.

3)The body of traction unit are precision machining from GB steel,and then plate hard chrome for solidity and anti-rusty.It is elegant appearance and follow environmental protection.

Ⅱ. Crusher:

1)The knives of machine is famous special steel.It is high hardness,strong wear-resistance and good toughnes.And it is especially durable,and high crushing ability to easily crush all kinds of soft and hard materials.

2)The tool carrier is designed with hollow structure,which is to stably run,smallwind-resistance,radiate fast and durable.

3)The body of machine are welded from high-strength GB steel,It is durable.

4)The stander are welded with GB U-steel and fixed with screws to keep the stability of machine.

5)The bearing with famous brand is stable and durable.

6)Theflywheel and pulley are casting and precision machining.Fly-wheel and pulley design gives higher inertia,which is durable.

7)The bottom of machine is equipped with foot shock,can actively adjust the balance of machine.

8)The cabinet of machine is designed with soundproof cotton.So the noise is low when working,which meets the requirements of environmental protection.

9)Within thicknes:0.2~3.5mm of materials can be crushed.The special thickness of materials shallbe noted.

Ⅲ.Blower:

1)The base of blower are designed with GB angle bar.And the motor i from famous brand to ensure quality.It is environmental protection, health and durable.

2)The cover and blades of blower are welded with stainless steel,which is never rust,environmental protection and durable.

3)The special design of blade of blower increase the pressure to achieve the good effect.

Specification parameters

|

Parameters |

Model |

DLF-800 |

DLF-800L |

DLF-1000 |

DLF-1200 |

DLF-1000L |

DLF-1200L |

DLF-1200XL |

|

The power of main motor (KW) |

67.5 |

· 11/×15 |

●15 |

●15/×22 |

●30 |

☆37/645 |

☆45/055 |

|

|

The power of blower (KW) |

●4/÷5.5 |

●4/.5.5 |

●4/÷5.5 |

●4/x5.5 |

05.5/.7.5 |

●7.5/÷11 |

●7.5/*11 |

|

|

The power of tractor (KW) |

●1.5 |

●1.5 |

●1.5 |

●1.51-2.2 |

●2.2 |

●2.2×3.7 |

●3.7 |

|

|

The fixed knives (PCS) |

4 |

4 |

4 |

4 |

4 |

4 |

4 |

|

|

The rotating knives (PCS) |

6 |

6 |

6 |

9 |

6 |

●9/<15 |

6 |

|

|

Knives material |

DC53、Special steel |

DC53 |

||||||

|

The dia.of screen mesh h(M) |

●9.5、☆10.5、☆12 |

●10.5、☆12.5、÷14.5 |

||||||

|

The size of crushing chamber(MM) |

800×250 |

800×330 |

1000×330 |

1200×330 |

1000×400 |

1200×400 |

1200×600 |

|

|

Crushing capacity (KG/H) |

200~300 |

300~500 |

300~500 |

300~500 |

500~700 |

700~900 |

900~1200 |

|

|

The noise when crushing(DB) |

65~85 |

65~85 |

65~85 |

65~85 |

65~85 |

65~85 |

65~85 |

|

|

The feeding blower |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

|

|

Cyclone separator |

☆ |

☆ |

☆ |

Lu |

☆ |

☆ |

||

|

Storage tank |

☆ |

☆ |

☆ |

☆ |

☆ |

☆ |

☆ |

|

|

The size of machine L×W×H(MM) |

1800*1050*2000 |

1800*1050*2000 |

2000*1050*2000 |

2200*1050*2000 |

2200*1050*2000 |

2350*1750*2100 |

2600*2100*2350 |

|

EN

EN CN

CN